Thursday, October 30, 2008

A New Solar Energy Era

The manufacturers are supposed to consider the following steps:

1. Slow down the manufacturering;

2. Put more money on the R&D;

3. Keep the experienced staffs;

4. Secure the next years projects;

5. Prepare for the warm-up of economy estd. in mid-2009.

Monday, October 20, 2008

Has The Sun Set On Solar Power?

A good article from The Age (Australia)

Has the sun set on solar power?

March 11 2003

Around the world solar power is booming, but locally the curtailing of government rebates has left the industry under a cloud. Melissa Fyfe reports.

Right Picture: JOE CASTRO, Steve Ingrouille, general manager of Going Solar.

Even if you are a hardy regular at the Queen Victoria market, chances are you will notice nothing different this week when you buy your meat or fish. And when you pass the barking toy dogs, leather jackets and moccasins, you will probably not notice that, above you, 1300 solar panels are harnessing the sun in the biggest solar power project in the southern hemisphere.

The photovoltaic, or PV, panels cover 2000 square metres across Shed D, E and part of C. Although more than 100 years old, the heritage sheds were built at the perfect angle and position for solar panels.

The panels were connected to the grid last week and will generate enough electricity each year to power 63 homes, supplying between 40 and 60 per cent of the market's power for 30 years. That's a lot of refrigerated meat and fish.

The project, funded with $1 million from the City of Melbourne and $750,000 from the Australian Greenhouse Office, will be a showcase of sustainable energy.

"The Queen Victoria Market is an icon and to have solar panels there is an enormous demonstration of what you can do with solar PV," says the AGO's Gerry Morvell, executive manager of sustainable energy.

A demonstration, yes, but unfortunately a rare one. The Queen Victoria project is a bright spot in an otherwise cloudy period for the solar industry.

Elsewhere in the world solar power is booming, with sales growth similar to that of mobile phones in the 1990s. Sales are doubling every two years and by 2010 the industry turnover is expected to be $US80 billion ($A130 billion).

The Australian solar market, however, is faltering. Grid-connected PV systems - at around $14,000 after a $7500 government rebate - are still too expensive for most people.

This means that it is a clean and green power choice, but only for the middle and upper classes. Steve Ingrouille, owner of retail shop Going Solar, says his customers usually are those with a bit of excess money.

"People are doing it because they believe in it and not for an economic return. They put solar panels on their roof rather than buy a new car. These are real pioneers because they are willing to put up the money."

While solar hot water systems are selling well - about 4.7 per cent of Australian households have solar-powered hot water- grid-connected systems that provide households with electricity are not. (Solar panels rarely provide the total energy needs of a house, but if people have solar hot water and are energy efficient the panels can provide the bulk of it.)

The Sustainable Energy Authority Victoria issues State Government rebates for up to 300 solar hot water systems each month but only 15 Federal Government rebates for panels - and that will drop to three with the Commonwealth's recent decision to cap the successful rebate scheme.

Victorians have actually gone backwards in their purchasing of solar panels. Over the three years of the Federal Government's rebate scheme, Victorians have gone from using $297,000 of rebates a month for grid-connected systems to only $90,000.

The rebate was designed to encourage solar power so that prices would come down in a bigger market. This has happened in countries such as Japan, where the rebate is twice as generous as Australia's. The cost of PV panels there has dropped by 75 per cent, says SEAV chief executive David Young. Two Australian companies, Origin Energy and Pacific Solar, have successfully tested panels that use much less silicon, the ingredient that makes solar power so expensive.

But both firms are unsure of the next step in Australia while Federal Government support seems shaky. They say Australian solar power is at a crossroads: with continued government support it will experience the worldwide boom or without support will lose its historic leading edge in solar technology.

Australia needs to ride the global wave of growth with a strong domestic market or risk losing its expertise, says Andrew Stock, Origin's executive general manager for generation. "If you fall off the wave it is hard to get back on it."

While Federal Government sources wonder if some of this industry angst is to do with "pre-budget skirmishing" - the Commonwealth will not indicate whether it will continue its rebate scheme in the May budget - there are wider concerns about the Howard Government's support for renewable energy.

At the end of last year, the Federal Government stopped funding the Co-operative Research Centre for Renewable Energy. Meanwhile, four Co-operative Research Centres for fossil fuels won $68.5 million in funding from the Commonwealth. The Howard Government also gave $35 million to mining, coal and aluminum company Rio Tinto for the Rio Tinto Foundation for a Sustainable Minerals Industry. The grant - double the funding for renewable energy research and development for the past seven years - raised the ire of environmentalists.

In a speech to the Senate in December, Greens leader Bob Brown questioned the amount of money going to fossil fuel companies and research bodies. He also questioned the role of Australia's Chief Scientist, Dr Robin Batterham, who is also chief technologist for Rio Tinto.

"What influence did Dr Batterham, who is a spokesperson for Rio Tinto, have in seeing that that money went to studies to advantage that company, at the same time that the body on which he sits decided to de-fund renewable energy?" Senator Brown asked.

At the time of Senator Brown's attack, federal Science Minister Peter McGauran defended Dr Batterham as an "extraordinarily admired" and respected chief scientist. Senator Brown's conflict-of-interest accusation was an incredible and almost unbelievable allegation, he said.

At the Australian National University - leaders in solar technology - the end of research and development funding for renewable energy has meant that one person a fortnight is losing their job.

The renewable energy sector is also jittery over a Council of Australian Governments report that has recommended the abolition of the Mandatory Renewable Energy Target, a key industry incentive.

The Federal Government says that it has supported renewable energy and is proud of its successful solar panel rebate scheme. While unable to comment on the future of the scheme, Catherine Job, the spokeswoman for federal Environment Minister David Kemp, says the Government is keen to support the solar industry while it establishes itself and develops an economy of scale.

But the Federal Government quotes International Energy Agency predictions that, even in a couple of decades, renewable energy will make up only a small percentage of the world's power sources.

In the meantime, the Federal Government argues that science must be used to clean up the coal industry and deal with greenhouse gases in a better way. One of these ways is geosequestration - or putting carbon dioxide underground instead of letting it warm the atmosphere. Millions of dollars will be spent on testing this technology, although environmentalists and some experts worry that it is unproven and expensive.

It is also important that technologies such as solar become self-sufficient in the future, Ms Job says. "The success of the solar industry in the long term should not be dependent on the rebate."

But recent events show the industry is indeed dependent on the rebate - at least right now. The industry lost 90 per cent of its sales overnight recently after the Federal Government capped the rebate scheme.

A shocked industry was told that for the next four months the rebate would be capped at a $100,000 a month. This means that in Victoria, only three customers each month could get the Commonwealth's rebate on PV panels.

Victoria's rebate waiting list has an estimated 50 customers, while South Australia has 60 people who applied this month alone.

It is fair to say that the industry is angry and disappointed, and that's putting it politely. Its predictions are grim: jobs will be lost and sales dead. According to a briefing paper from the Australian Business Council for Sustainable Energy, "There appears little point in trying to sell to customers over the next five months."

The reason for introducing the cap was simple: the Commonwealth pot of rebate money, administered by the Australian Greenhouse Office, had almost run out. Although the industry estimated the $31 million scheme would last until September, no one, not even the AGO, had factored in the recent behaviour of South Australians.

Hit by electricity price hikes, South Australians suddenly became enamoured with solar power at the end of last year - so much so that they almost bankrupted the rebate scheme. South Australians went from using $102,000 worth of rebates each month to $316,000.

When the AGO realised this, it decided to cap the monthly rebate to slow the scheme instead of letting the funds quickly run out. Ms Job says the Federal Government is confident there will be no job losses in the industry as installers still have six months of work.

She dismisses the suggestion that the AGO could swap money into the rebate scheme, saying there are no areas of "underspend" in the office. "There was a finite pot of money and the industry always knew that."

Melissa Fyfe is The Age's Environment Reporter.

Friday, October 17, 2008

Processing Steps Of Thin-film Solar Cell

Tuesday, October 14, 2008

Solar Panels Installing In UK

www.solartwin.com/

www.greenworks-energy.co.uk

www.rayotec.com/

www.solarfusionltd.co.uk

www.greensystemsuk.com

Monday, October 13, 2008

Solar Cells Manufacturing Process

The cells manufacturing process should be based on first-class solar cell manufacturing equipments. Factory workers combine the patented technology of intensive back surface field with proprietary research and development, which makes us a top level international manufacturer of solar cells and PV modules.

Advanced diffusion techniques are normally adopted, in order to ensure the homogeneity inside of the cells, and reduce the matched losses among the cells. Advanced PECVD film forming technique to plate the surface of the cells with a deep blue film of SiN anti-reflective coating, which results in a beautiful look of the uniform colour, is also needed.

By utilizing high quality metal size to make the back surface field and electrode, factory can ensure the good conductivity and reliable adhesion force and very good solderability of the electrode. The high accurate printing pattern makes the automatic soldering of the cells easy.

The careful and consistent handpicking of identical and high efficiency solar cells reduces the matched losses of the cells and enhances the power of modules. The use of durable aluminium frames make easy mounting possible and enhances the load capability of the modules.

Normally the R&D team sets up before the company established.

Solar Cells and Solar Systems

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers (such as Jetion) add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process.

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers (such as Jetion) add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process. Solar cells are usually mounted in large arrays known as ‘solar modules’ electrically interconnected and sealed under toughened glass to protect them from the weather. Solar modules, together with various system components such as batteries, charge controllers and inverters, form the basis of a complete solar power system.

Solar power systems can be connected to the electricity grid or used in isolated units, as ‘off-grid’ power. When electrical grid connection is possible, any excess electricity can be fed back into the system and sold. Off-grid systems are found where grid access is physically difficult or economically unattractive, such as portable, remote, off-shore locations or developing countries.

Friday, October 10, 2008

Building integrated photovoltaics

Due to specific task cooperation of many different experts, such as architects, civil engineers and PV system designers, is necessary. According to how and where such systems are built, whether into the facade or in the roof, the following BIPV systems are recognized:

- Facade or roof systems added after the building was built

- Facade integrated photovoltaic systems built along with an object

- Roof-integrated photovoltaic systems built along with an object

- "Shadow-Voltaic" - PV systems also used as shadowing systems, built along with an object or added later

Tuesday, October 7, 2008

Solar Cells Sale In China

About the revenue: 2006 China Solar Cell revenue was 1251.4 Million USD,Increased 264.5% than 343.3 Million USD in 2005,and est. reached 3188.6 Million USD in 2007,increased 154.8% than 2006.

About utilization: the total solar cell utilization of China is 27.36 in 2005, 34.24% in 2006, about 41.61% in 2007, est. 76.99 in 2012; the low utilization during 2005 and 2006 mainly because the following two reasons: first, the expansion of solar cell manufacture capacity is fast; second, the shortage of solar cell raw material(wafer or polysilicon) is tremendous.

Monday, October 6, 2008

Solar Cells Blog

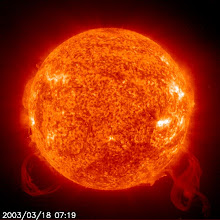

Solar power generation technology is founded upon silicon, a common element that comprises approximately 25% of the earth’s crust by mass. When light falls on high purity silicon, the PV (photovoltaic) effect causes the release of electrons from the silicon atoms. When silicon is fashioned into a solar cell with collection electrodes, the PV effect generates an electrical current.

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process.

The increased awareness on renewable energy and climate change has led to demand of solar power elements outstripping supply with Government subsidies and falling costs and prices continuing to support the industry growth. Many companies had already begun to produce massive solar cells to fulfill the thirsty market.