Monday, December 29, 2008

Be Careful of Cells / Panels Made in Zhejiang

Friday, October 17, 2008

Processing Steps Of Thin-film Solar Cell

Monday, October 13, 2008

Solar Cells Manufacturing Process

The cells manufacturing process should be based on first-class solar cell manufacturing equipments. Factory workers combine the patented technology of intensive back surface field with proprietary research and development, which makes us a top level international manufacturer of solar cells and PV modules.

Advanced diffusion techniques are normally adopted, in order to ensure the homogeneity inside of the cells, and reduce the matched losses among the cells. Advanced PECVD film forming technique to plate the surface of the cells with a deep blue film of SiN anti-reflective coating, which results in a beautiful look of the uniform colour, is also needed.

By utilizing high quality metal size to make the back surface field and electrode, factory can ensure the good conductivity and reliable adhesion force and very good solderability of the electrode. The high accurate printing pattern makes the automatic soldering of the cells easy.

The careful and consistent handpicking of identical and high efficiency solar cells reduces the matched losses of the cells and enhances the power of modules. The use of durable aluminium frames make easy mounting possible and enhances the load capability of the modules.

Normally the R&D team sets up before the company established.

Solar Cells and Solar Systems

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers (such as Jetion) add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process.

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers (such as Jetion) add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process. Solar cells are usually mounted in large arrays known as ‘solar modules’ electrically interconnected and sealed under toughened glass to protect them from the weather. Solar modules, together with various system components such as batteries, charge controllers and inverters, form the basis of a complete solar power system.

Solar power systems can be connected to the electricity grid or used in isolated units, as ‘off-grid’ power. When electrical grid connection is possible, any excess electricity can be fed back into the system and sold. Off-grid systems are found where grid access is physically difficult or economically unattractive, such as portable, remote, off-shore locations or developing countries.

Tuesday, October 7, 2008

Solar Cells Sale In China

About the revenue: 2006 China Solar Cell revenue was 1251.4 Million USD,Increased 264.5% than 343.3 Million USD in 2005,and est. reached 3188.6 Million USD in 2007,increased 154.8% than 2006.

About utilization: the total solar cell utilization of China is 27.36 in 2005, 34.24% in 2006, about 41.61% in 2007, est. 76.99 in 2012; the low utilization during 2005 and 2006 mainly because the following two reasons: first, the expansion of solar cell manufacture capacity is fast; second, the shortage of solar cell raw material(wafer or polysilicon) is tremendous.

Monday, October 6, 2008

Solar Cells Blog

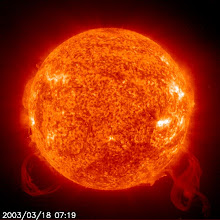

Solar power generation technology is founded upon silicon, a common element that comprises approximately 25% of the earth’s crust by mass. When light falls on high purity silicon, the PV (photovoltaic) effect causes the release of electrons from the silicon atoms. When silicon is fashioned into a solar cell with collection electrodes, the PV effect generates an electrical current.

Solar cells are produced from raw silicon materials in a multistage process. Firstly raw quartzite sand is processed into bulk silicon, which is subsequently melted and formed into blocks or ‘ingots’. The ingots are cut and sliced to produce ‘wafers’ which form the basis of a solar cell. Solar cell manufacturers add electrodes to the wafer for electrical connectivity. The wafers are then cleaned and treated prior to their introduction into the manufacturing process.

The increased awareness on renewable energy and climate change has led to demand of solar power elements outstripping supply with Government subsidies and falling costs and prices continuing to support the industry growth. Many companies had already begun to produce massive solar cells to fulfill the thirsty market.